FREEZING IQF OCTOFROST™ SHRIMP

01 Wed, 2019

MARKET TRENDS

Today, nearly 90% of exports of marine products are in frozen form with frozen shrimp having the largest share. IQF shrimp consumption is expected to continue to grow along with the increase of seafood consumption.

TYPICAL PRETREATMENT

Pretreatment practices can differ a lot depending on the shrimp variety and it can be anything from peeling, blanching, cooking or glazing.

PRODUCT CHARACTERISTICS

Shrimp is a high value product which needs extra care in handling due to its sticky texture, fragile antennas and high water content..

COMMON CHALLENGES

Preserving the natural appearance

The natural appearance of the frozen shrimp is crucial: antennas must be intact and lump formation should be avoided for a premium selling price.

Energy consumption

Energy consumption during shrimp processing is high, which challenges the profitability of the processor. Finding energy efficient technologies is an important aspect.

Reliable Food Safety

Shrimp requires many times intensive manpower which increases food safety hazards. In addition, the sticky texture of shrimp can make the processing equipment harder to clean which increases the risk of cross contamination between product batches.

OCTOFROST™ FREEZING IQF SHRIMP

OctoFrost™ freezer is an optimal freezer for IQF shrimp with several specific technical features which contribute to:

- Natural appearance.

OctoFrost™ freezer is designed with multiple freezing zones – each with an adjustable fan speed, therefore the optimal airflow in each zone preserves the shrimp antennas, natural appearance and shape of shrimp with no curling effect.

- Good product separation

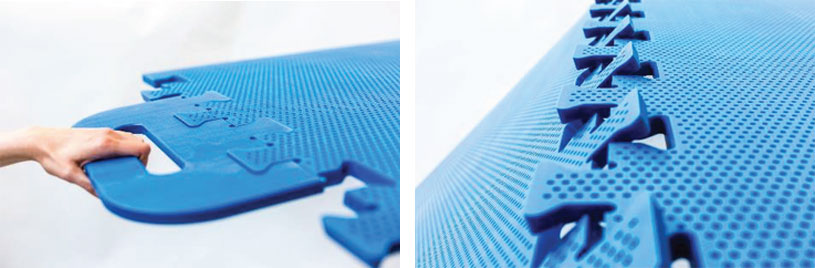

The asymmetric movement of the OctoFrost™ bedplates plays an important role in a good product separation, especially in the case of sticky peeled shrimps.

- Energy Efficiency and High Yield

The speed of the OctoFrost™ fans can be adjusted with the frequency converters which allows fully customized airflow for each product type in each of the freezing zones. The energy savings can reach as high as 30%.

The quick crust-formation locking the moisture of the shrimp and keeping the dehydration to minimum. This results in a premium IQF shrimp to be sold.

- Food Safety.

OctoFrost™ freezer requires much less manpower when compared to other technologies. With OctoFrost™ food safety features such as the free-standing design, bedplates which can be cleaned outside the freezer without stopping the production, lack of joints, easy access for cleaning, and cleanable design – a reliable food safety can be achieved by shrimp processors.

Our experts are available to help you: sales@octofrost.com

Related Post

The true fishmeal carbon footprint

The established Life Cycle Analysis (LCA) methodology to assess the fishmeal carbon footprint only accounts for the vessel fuel and post-harvest processing energy while ignoring the carbon sequestration potential of fish.

View more

Freezing Tropical Fruits: Convenient and Effective Solution with Octofrost Machines

Tropical fruits are always a great choice for providing nutrition and fresh flavor to daily meals.

View more